The new unique Auto Vibration Analyzer VSHOOTER+® is able to easily and quickly analyze rotating machine like an electrical motor or a pump or a fan or a bearing housing […]

The new unique Auto Vibration Analyzer VSHOOTER+® is able to easily and quickly analyze rotating machine like an electrical motor or a pump or a fan or a bearing housing or a spindle.

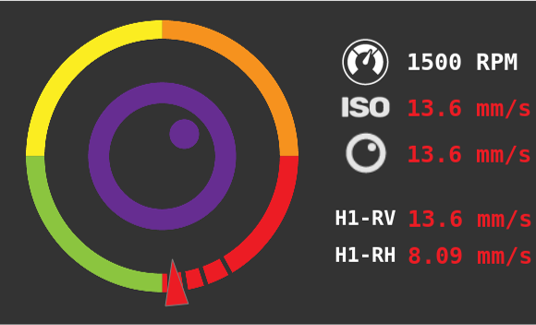

Take a photo, do the measurements and get the MCP (Machine Condition Picture) to see the machine condition, if maintenance needed at a glance. Quick, easy to use, with automatic auto diagnosis system for beginners and experts.

Comparing to the former Auto Vibration Analyzer VSHOOTER® model, the new vibrometer engineered by SYNERGYS TECHNOLOGIES has now got :

– Large 5.7” touch screen

– Infrared thermal camera LEPTON FLIR 160X120px

– Overall Improvement of the soft, more intuitve

– New embeded software BALISHOOTER® to automatically focus on UNBALANCE or MISALIGNMENT severity vibration problems

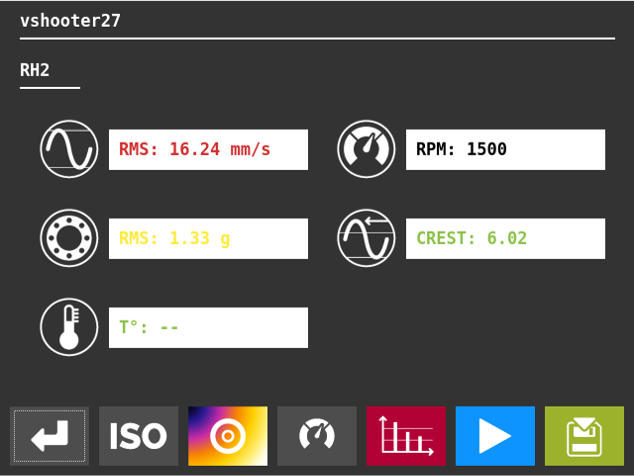

The big adavantage of this vibrometer is its special dedicated MCP (Machine Condition Picture) firmware,VSHOOTER+® automatically diagnoses the machine excessive vibration causes like the Unbalance, the Misalignment, the Looseness, the Bearinglubrication….

The MCP result is given around the machine picture (embedded visiblecamera) with an Easy-to-Understand summary table with all vibration

problems and color indications.

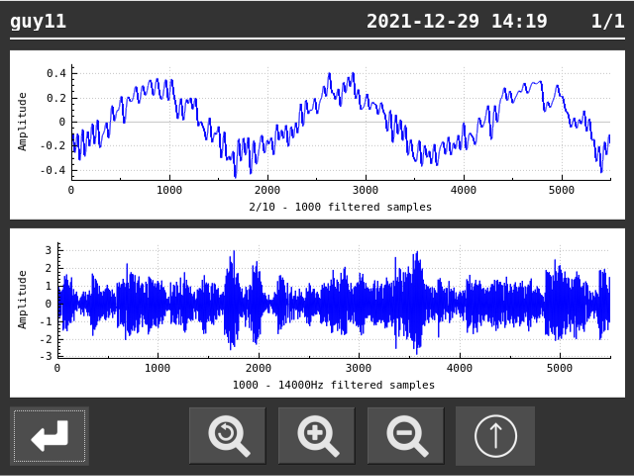

VSHOOTER+® measures vibration Trending Overall values (ISO RMSBearing-T°), FFT spectrums values and Time Signal values.

Of course, you can store all the measurement data in the memory todownload to PC to create your own reports.