Discover a new vibration analysis experience unique in the world. The VSHOOTER®-3-WL. The VSHOOTER®-3-WL is the ideal equipment for predictive maintenance of rotating machines. This is a vibration analyzer that […]

The VSHOOTER®-3-WL is the ideal equipment for predictive maintenance of rotating machines.

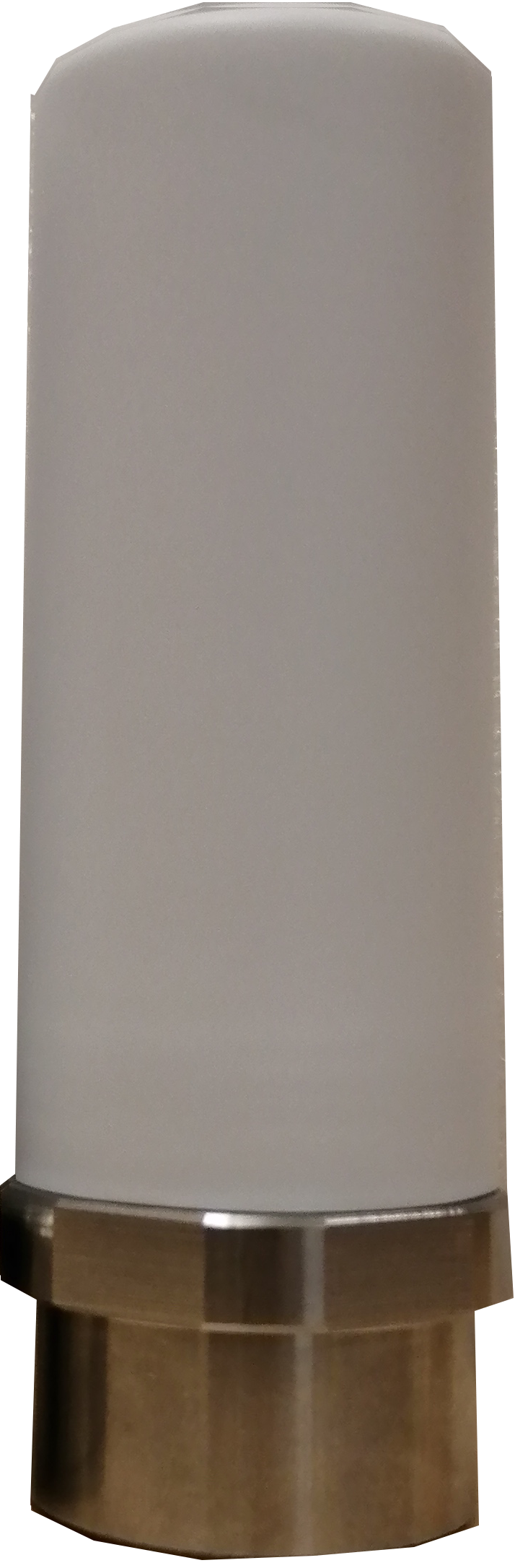

This is a vibration analyzer that works with a wireless triaxial sensor and a rugged smartphone which has on-board data processing software.

There are 4 differents versions :

– The Standard Version VSHOOTER®-3-WL

– The Standard Version with an infrared camera (80×60 px, 9Hz) VSHOOTER®-3-WL-IR

– The Standard Version with an HD infrared camera (256×192 px, 25 Hz) VSHOOTER®-3-WL-IR HD

– The Standard version which is ATEX Certified (Smartphone Ex ib Ⅱ CT4Gb, Capteur : Ex ia Ⅱ CT4Ga) VSHOOTER®-3-WL EX

With it you will be able to quickly find vibration defects in rotating machines such as :

Electric motors, pumps, fans, rolling bearings or even machine tool spindles.

In addition, the wireless triaxial sensor will allow you to make only one measurement for analyze the 3 axes of vibrations.

This one aim to provide the data necessary for the software to analyze your rotating machine in detail.

The VSHOOTER®-3-WL software has a special MCP (Machine Condition Picture) program, it will automatically measure and diagnose dangerous machine vibrations like misalignment, foundation/loosening issues, bearing faults or still the unabalance.

Finally, a colored severity indicator will be displayed after taking the measurement to see what the problem is.

Like the VSHOOTER®+ we have developed intuitive and easy-to-use software with which you will make global measurements RMS – FFT spectrum – Time signal – Trend curve.

Of course you can tranfer data and reports to your PC via USB-C connection.

Below you can see a thermal image of the VSHOOTER®-3-WL IR device.